April 16, 2024

Sourcing HVAC Ductwork for Commercial Construction Quality, Reliability, Affordability In commercial construction, the selection of HVAC ductwork is more than a necessity; it’s a choice […]

March 14, 2024

Direct Duct Sales & Sourcing Excellence Unveiling The Cincinnatus Group Advantage Whether it’s new construction or commercial renovation, the reliability and quality of HVAC ductwork […]

February 13, 2024

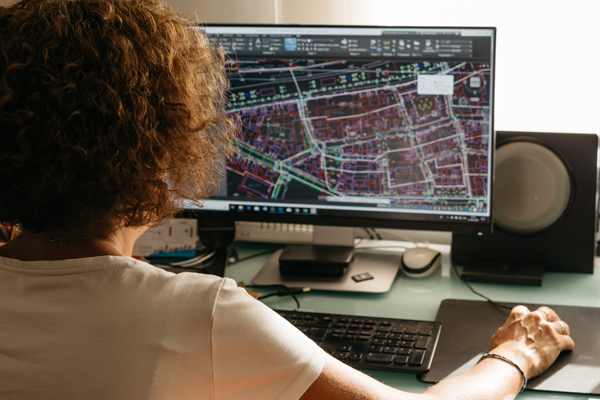

Affordable White-Label CAD & BIM Services for Your Business In 2019, The Construction Labor Market Analyzer estimated that when tallying both direct and indirect labor […]

January 15, 2024

How to Offer HVAC Duct Detailing Services and Supercharge Your Brand Set Your Business Apart with Affordable White-Label CAD & BIM Services The HVAC duct […]

December 13, 2023

How CAD and BIM Services Streamline Commercial Construction Delivering Efficiency and Cost Savings The integration of Computer-Aided Design (CAD) and Building Information Modeling (BIM) technologies […]

November 14, 2023

The Benefits of Outsourcing HVAC CAD & BIM Services From Cost Savings to Enhanced Precision In the evolving world of HVAC (Heating, Ventilation, and Air […]

October 11, 2023

Enhance Your Brand with CAD & BIM Services How to Give Your Business a Cutting-Edge Advantage In today’s fast-moving marketplace, businesses are on the lookout […]

September 13, 2023

Three Secrets of Great HVAC Fabrication Project Management Precision Estimates, Order Accuracy, and Clear Communications When you think about the HVAC industry, a few key […]

August 9, 2023

The Importance of Workflow in HVAC Duct Fabrication How Poor Project Management Blocks Profits HVAC Duct Fabrication is a complex process requiring a high degree […]

July 12, 2023

Project Management for HVAC Duct Fabricators The Helping Hand You Need to Build Your Fabrication Business You know the story: your fabrication shop produces high-quality […]

June 15, 2023

Choosing the Right Rooftop Duct Supports for Your HVAC System In commercial HVAC installations, rooftop duct supports are crucial in maintaining the integrity of the […]

May 10, 2023

The Importance of Rooftop Supports in HVAC Have you ever looked up at a commercial building and noticed the various equipment and features mounted on […]

April 16, 2023

Air Quality and Air Purification in HVAC Installations At The Cincinnatus Group, our specialty is systematic ductwork materials management. We source ductwork for commercial construction, […]

March 9, 2023

Which is Better, Rectangular or Spiral Duct? Choosing Rectangular or Spiral for Your Project Both spiral duct and rectangular duct are commonly used in […]

February 9, 2023

HVAC Duct Supplies without Headaches Systematic Ductwork Sales & Materials Management Looking for a reliable supplier of commercial HVAC duct, roof supports, transitions, connectors, and […]